Cleaning water via electrochemical oxidation

Australian researchers have used electricity to clean up heavily polluted industrial wastewater.

Scientists from the University of Sydney’s School of Chemical and Biomolecular Engineering developed an electrochemical oxidation process with the aim of cleaning up complex wastewater that contains a toxic cocktail of chemical pollutants.

They hope the findings will help wineries, pharmaceutical manufacturers and other industries that must comply with strict wastewater regulations.

Led by Associate Professor Alejandro Montoya and PhD candidate Julia Ciarlini Junger Soares, the engineers developed a solution to clean a specific type of contaminated water.

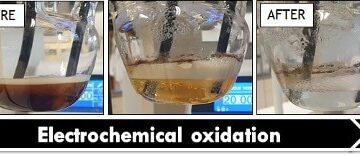

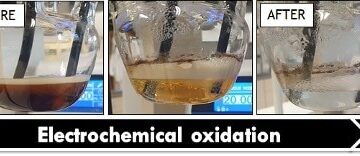

The water before, during and after treatment. Credit: Julia Ciarlini Junger Soares, University of Sydney

The water before, during and after treatment. Credit: Julia Ciarlini Junger Soares, University of Sydney

“Our study, published in Algal Research, involved industrial wastewater that had been heavily contaminated with a cocktail of organic and inorganic species during a biofuel production process,” Soares said.

The wastewater, which contained carbon, nitrogen and phosphorus, was generated in a pilot plant, designed by the team for the production of biofuels using naturally abundant micro-algae.

“We have employed an incredibly powerful process that eliminates even the most persistent non-biodegradable pollutants, such as pharmaceuticals and pesticides, as well as various classes of organic compounds that can be found in many industrial effluents,” she said.

The process involved treating wastewater with electricity using specialised electrodes. These discharged electricity, driving oxidation reactions near the electrode surfaces that transformed the organic contaminants into harmless gases, ions and minerals.

It does not require the addition of chemicals or severe operation conditions, and does not produce additional waste streams.

“Wastewater is a significant issue for our environment, as well as for many industries who use substantial volumes of water in their processes, such as in reactions, transport, and washing and cooling. Finding suitable solutions for reuse or disposal is often very challenging and costly,” Soares said.

“The electrochemical method that we used can be readily applied to industries that must comply with strict regulations for wastewater disposal, such as pulp and paper processing, wineries, as well as pharmaceutical production facilities.”

The engineers are carrying out further research on specific contaminants to better understand the chemical transformations that take place during electrochemical oxidation.

“Worldwide, researchers are investigating methods for the development of biofuels from algae. Developing alternatives for the treatment and reuse of this industrial effluent is a hot research topic and can bring opportunities for energy and resource recovery within a circular bio-economy framework,” Soares said.

“I think it’s important to keep pushing for and developing this process because it definitely works well for organic pollution. As we develop more and more renewable energy sources and processes, then we could supply that kind of energy to the system.”